Prototyping & Tooling

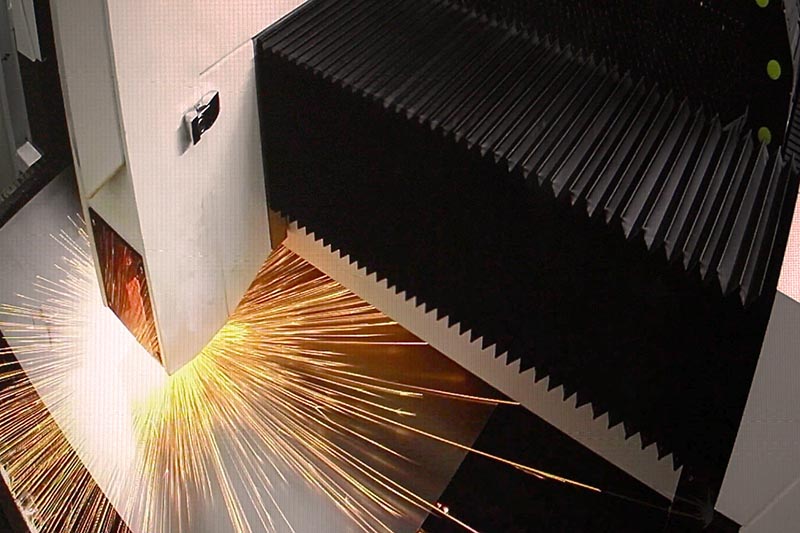

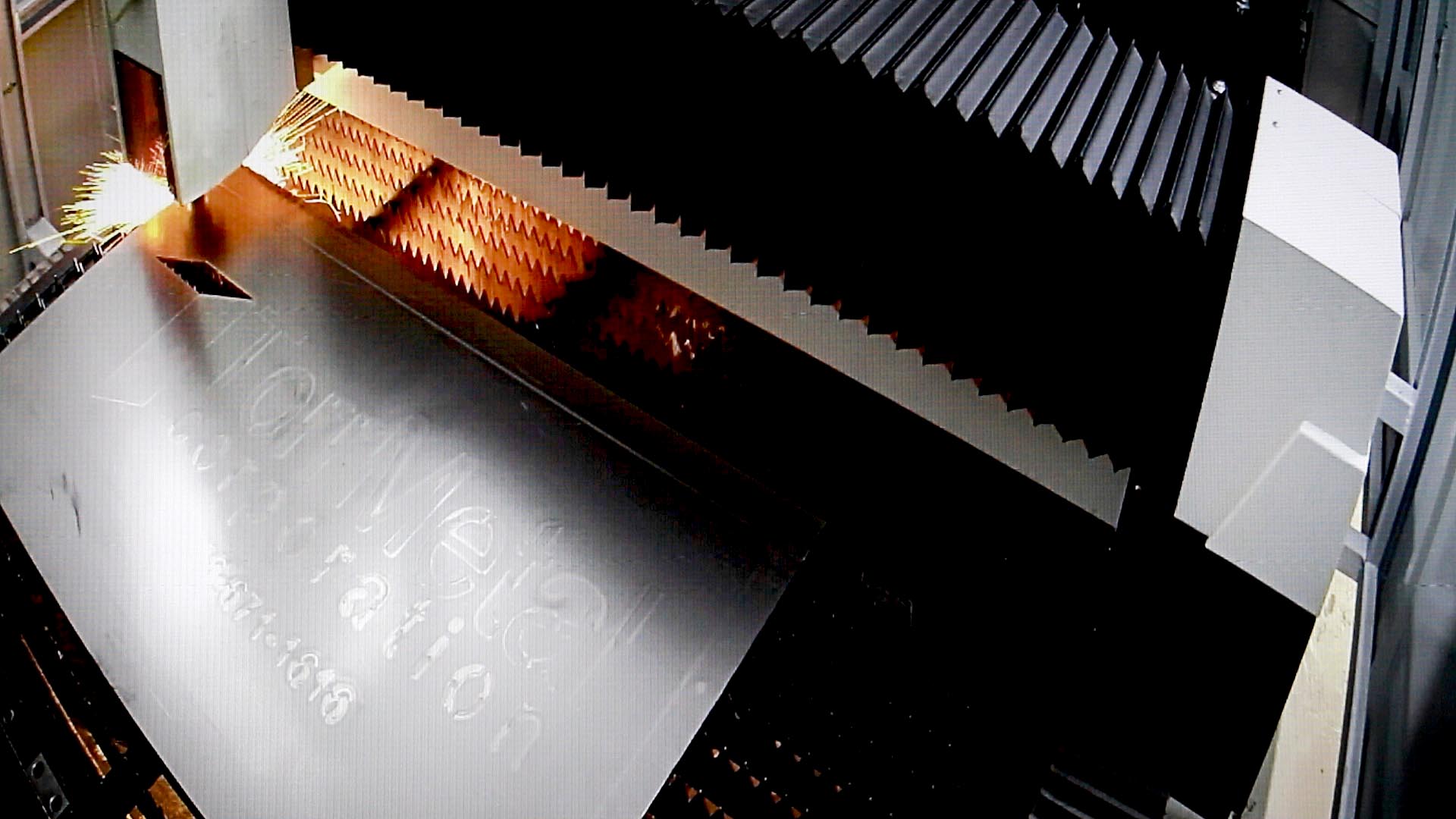

Fiber Laser, Wire EDM, CNC Milling, and CNC Press Brake for Prototyping and Tooling Component Production

The MD+PRO III Advance delivers precision, quality and speed for all of your prototype, small lot production and tooling demands.

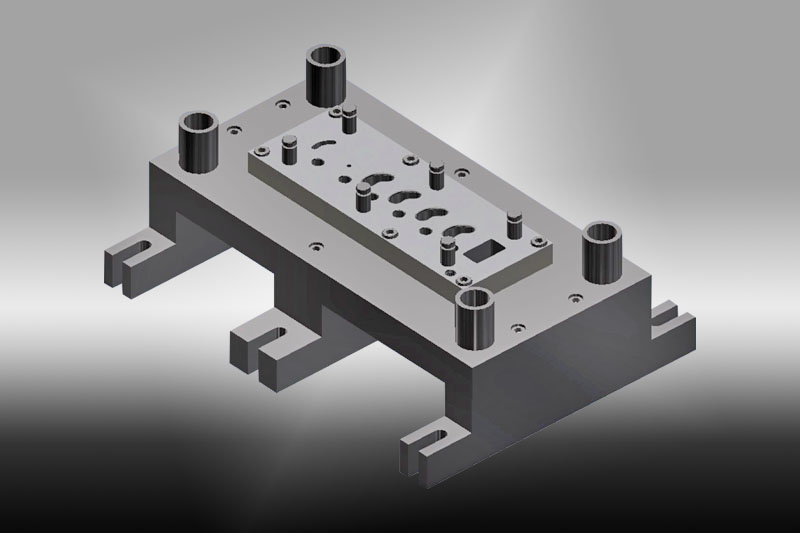

Our MD+PRO III Advance Wire EDM is world-class equipment that cuts high precision parts and tooling components. Our engineers will work with you to satisfy all of your small lot prototyping or concept part needs.

Wire EDM Specifications

| Inch | Metric | |

|---|---|---|

| Max. Submerged Workpiece Dimensions | 31.9 x 27.6 x 8.5 | 810mm x 700mm x 215mm |

| Max. Submerged Workpiece Weight |

1102 lbs | 500 kg |

| Machining Range X – Y | 15.7 x 11.8 | 400mm x 300mm |

| Max. Z-Axis Height | 8.7 | 220mm |

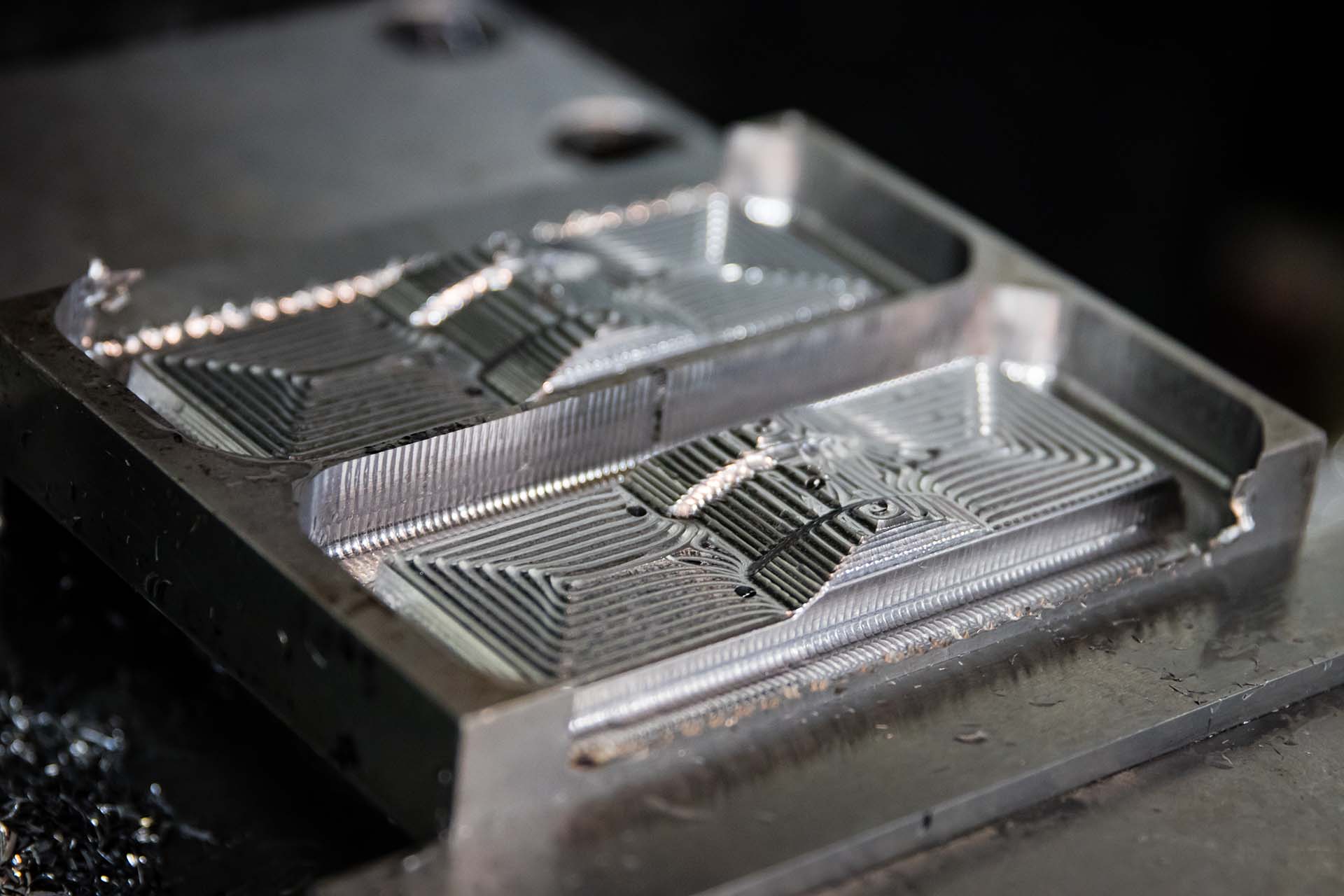

CNC Mill Specifications

| Inch | Metric | |

|---|---|---|

| X Y & Z Travel | 60 x 23 x 20.5 | 1524mm x 584mm x 520mm |

| Table Size | 76 X 14 | 1930mm X 520mm |

CNC Press Brake Specifications

| Inch | Capacity | |

|---|---|---|

| Amada FaB-50 D | 80″ Long Bed | 50 Ton CNC Press Brake |

Fiber Laser Wire EDM and CNC Milling Benefits and Applications:

- We cut high precision parts for prototyping

- Prototypes can be quickly produced for testing and further development.

- Easy transition to longer-run production with tooling component production.

- Small lot production when tooling is not practical or necessary.

- Fixture production for in-house or customer needs.

CNC Milling, Fiber Laser, EDM, and Press Brake Video

Find out how our services can meet your needs. Contact Us Today!

Metal Stamping

Metal Stamping